Understanding Plate Style Heat Exchangers: Efficiency and Application

Release time:

2025-07-29

Plate style heat exchangers are a crucial component in the realm of industrial heat transfer technologies. Designed to facilitate efficient thermal exchange between two fluids, these devices utilize a series of thin, corrugated plates stacked together to create channels for fluid flow. This design not only maximizes surface area but also enhances heat transfer efficiency, making them suitable for

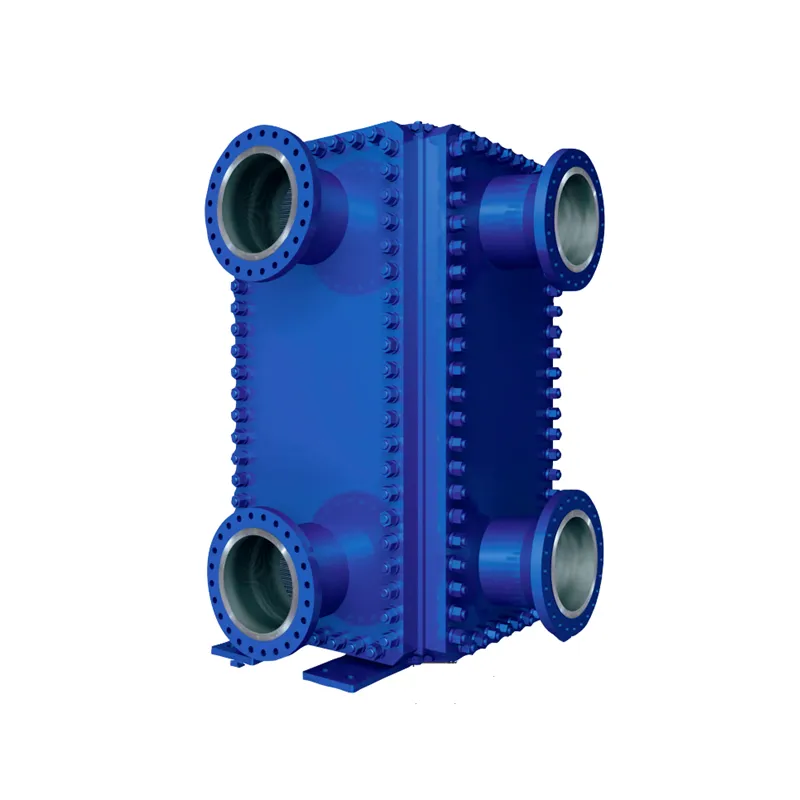

Plate style heat exchangers are a crucial component in the realm of industrial heat transfer technologies. Designed to facilitate efficient thermal exchange between two fluids, these devices utilize a series of thin, corrugated plates stacked together to create channels for fluid flow. This design not only maximizes surface area but also enhances heat transfer efficiency, making them suitable for a wide range of applications, including HVAC systems, chemical processing, and food production.

One of the primary advantages of plate style heat exchangers is their compact size. Compared to traditional shell-and-tube heat exchangers, plate exchangers occupy significantly less space while delivering superior heat transfer performance. This is particularly beneficial in settings where space is at a premium or where weight considerations are essential, such as in mobile installations.

The operational mechanism of plate style heat exchangers is based on the principle of counterflow or parallel flow, where two fluids move in opposite or the same direction, respectively. This allows for a high thermal exchange coefficient, which essentially means that heat can be transferred more effectively with minimal temperature difference between the fluids. The plates are typically made of materials such as stainless steel, which not only provides durability but also ensures resistance to corrosion and fouling, enhancing the lifespan of the heat exchanger.

Maintenance is another critical aspect of plate style heat exchangers. Their design allows for easy access to individual plates, making cleaning and inspection straightforward. Regular maintenance is essential to prevent fouling, which can significantly impact heat transfer efficiency. A well-maintained plate heat exchanger can operate at optimal performance levels, ensuring that processes remain efficient and energy consumption is minimized.

In terms of versatility, plate style heat exchangers can be configured in various ways to suit different operational needs. The number of plates in the assembly can be adjusted based on the required heat transfer area, allowing for customization based on specific temperature and flow rate requirements. This adaptability makes them an excellent choice for industries ranging from pharmaceuticals to energy production.

In conclusion, plate style heat exchangers are an excellent solution for efficient thermal management in industrial applications. Their compact design, high thermal efficiency, and ease of maintenance make them a popular choice among engineers and facility managers. By understanding the capabilities and advantages of these devices, professionals can make informed decisions that optimize performance and enhance operational efficiency in their respective fields.

Latest News

Why Choose Titanium Heat Exchangers Over Traditional Materials? Unveiling the Superior Benefits

Why Choose Titanium Heat Exchangers Over Traditional Materials? Introduction to Heat Exchangers In the world of industrial equipment and components, heat exchangers play a pivotal role in efficiently transferring heat between two or more fluids. They are essential in numerous applications, ranging from power generation to chemical processing. Traditionally, materials such as copper, aluminum, and

2025-07-30

Understanding Plate Style Heat Exchangers: Efficiency and Application

Plate style heat exchangers are a crucial component in the realm of industrial heat transfer technologies. Designed to facilitate efficient thermal exchange between two fluids, these devices utilize a series of thin, corrugated plates stacked together to create channels for fluid flow. This design not only maximizes surface area but also enhances heat transfer efficiency, making them suitable for

2025-07-29

A Comprehensive Guide to Wood Stove Heat Exchanger Types: Maximize Your Heating Efficiency

A Comprehensive Guide to Wood Stove Heat Exchanger Types When it comes to heating your home with a wood stove, understanding the various heat exchanger types is essential. Heat exchangers play a critical role in how efficiently your wood stove operates, impacting both fuel consumption and heat distribution within your living space. This comprehensive guide delves into the different types of wood s

2025-07-28

Understanding the Benefits and Applications of Stainless Steel Coil Tubing Heat Exchangers

In the realm of industrial equipment and components, stainless steel coil tubing heat exchangers stand out as vital devices for effective thermal management. These exchangers are designed to transfer heat efficiently between two or more fluids, making them essential in various applications across industries such as chemical processing, food and beverage, HVAC, and power generation. One of the prim

2025-07-27

Essential Guide: What to Look for in a Quality Fireplace Tube Heat Exchanger

What to Look for in a Quality Fireplace Tube Heat Exchanger When it comes to creating a cozy atmosphere in your home, a fireplace tube heat exchanger can significantly enhance the efficiency of your heating system. In this comprehensive guide, we will explore the critical aspects to consider when searching for a quality fireplace tube heat exchanger. We will cover everything from design and materi

2025-07-26

Stove pipe heat exchangers play a vital role in various industrial applications, particularly in processes requiring efficient heat transfer. These devices are designed to harness and optimize thermal energy exchange between fluids, thereby enhancing overall system performance. In this article, we will explore the construction, operational principles, and applications of stove pipe heat exchangers

2025-07-25