Rotary lobe pump

Keywords : Raystone

Classification :

PRODUCT DETAILS

Keywords : Chemical pumps

The company has advanced production, testing equipment, has a stable supply and marketing partners at home and abroad, with the most professional team to do the best customer service.

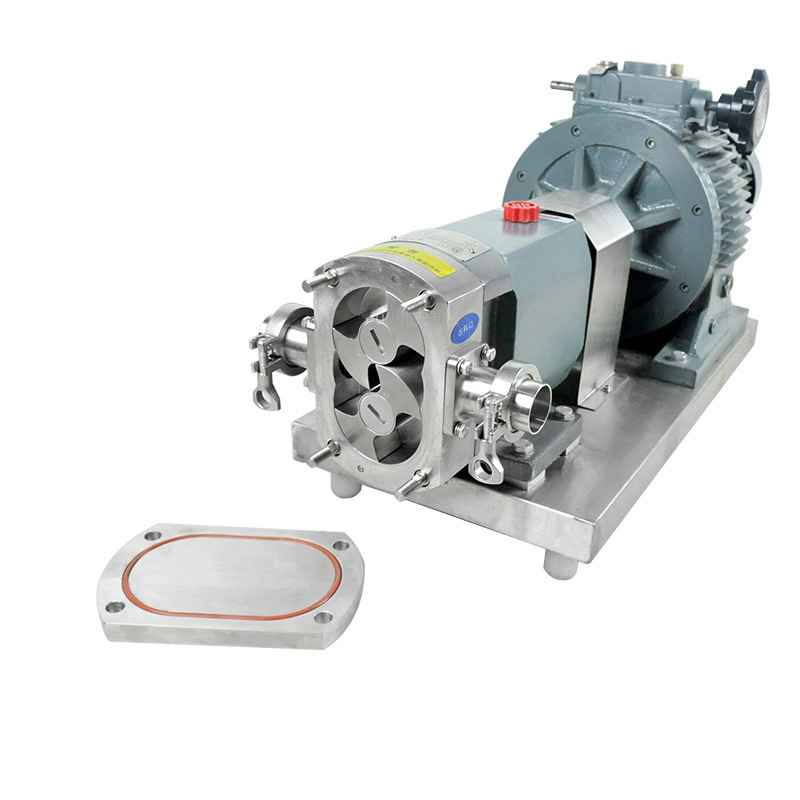

Rotary lobe pump is a positive displacement pump that plays an important role in many industrial fields.

1. Structure and Principle

Rotary lobe pump is mainly composed of pump housing, a pair of intermeshing cam rotors and synchronous gearbox. The pump housing is generally made of high-quality metal materials with good sealing and pressure resistance. The cam rotor has a unique shape, usually a three-leaf or multi-leaf structure, and its surface is smooth, which can ensure high efficiency and stability during operation.

When working, the synchronous gearbox ensures that the two cam rotors rotate synchronously and in opposite directions at a precise speed. When the rotors turn, multiple sealed chambers are formed between them and the pump housing. As the rotors rotate, these chambers move from the inlet side to the outlet side, thereby sucking in, conveying and discharging the fluid. This working principle enables the Rotary lobe pump to smoothly convey various fluids, whether it is high-viscosity fluids such as grease, mud, or fluids containing solid particles, they can be efficiently handled.

2. Product Features

Rotary lobe pump has a wide range of adaptability to fluids of different viscosities. When handling high-viscosity fluids, it will not experience a significant drop in flow or malfunction like some other pumps. For example, in food processing, it can smoothly transport high-viscosity materials such as chocolate paste; in sewage treatment, it can also easily treat sewage containing a large amount of sludge.

Due to its unique working method, the shear force generated during the fluid conveying process is very low. This is very important for some shear-sensitive materials, such as biological products and cosmetic raw materials. It can complete the conveying task without destroying the original properties of the material.

The flow of the rotary lobe pump is basically not affected by pressure fluctuations. As long as it is within the rated working range of the pump, it can maintain a stable flow output. This feature gives it a great advantage in precise batching and other links in chemical production.

3. Application areas

Used to transport various food raw materials such as milk, juice, jam, and edible oil. For example, in jam production, it can transport the cooked jam from the reactor to the packaging equipment to ensure that the texture and taste of the jam are not affected.

Transportation of chemical raw materials, such as various paints, coatings, glues, etc. In paint production, it can accurately mix raw materials of different components and transport them to the next process.

Used for sewage and sludge treatment. In sewage treatment plants, Rotary lobe pumps can transport sewage from one treatment unit to another, and can also effectively handle the transportation and discharge of sludge.

Transporting pharmaceutical raw materials, intermediates and finished pharmaceuticals. Due to its low shear force characteristics, it is very suitable for pharmaceutical production processes that require high stability of pharmaceutical ingredients.

With its unique structure and excellent performance, Rotary lobe pumps have become indispensable fluid transportation equipment in many industries.

Product Parameters

|

Model |

Theoretical Flow (m³/h) |

Flow Per turn (L/r) |

Flow rate per 100 rpm (L/100r) |

Theoretical Speed (r/min) |

Pressure (Mpa) |

Power (KW) |

Calibre |

|

B3 |

3 |

0.125 |

12.5 |

400 |

0.4Mpa |

1.1/1.5 |

(mm) |

|

B5 |

5 |

0.2 |

20 |

|

|

1.5/2 2 |

38-50.5 |

|

B10 |

11.3 |

0.47 |

47 |

|

|

4/5.5 |

38/45-64 |

|

B14 |

14 |

0.58 |

58 |

|

|

5.5/7.5 |

51-64 |

|

B20 |

20 |

0.83 |

83 |

|

|

15 |

63-77.5 |

|

B30 |

30 |

1.25 |

125 |

|

|

Power (KW) |

DN80 |

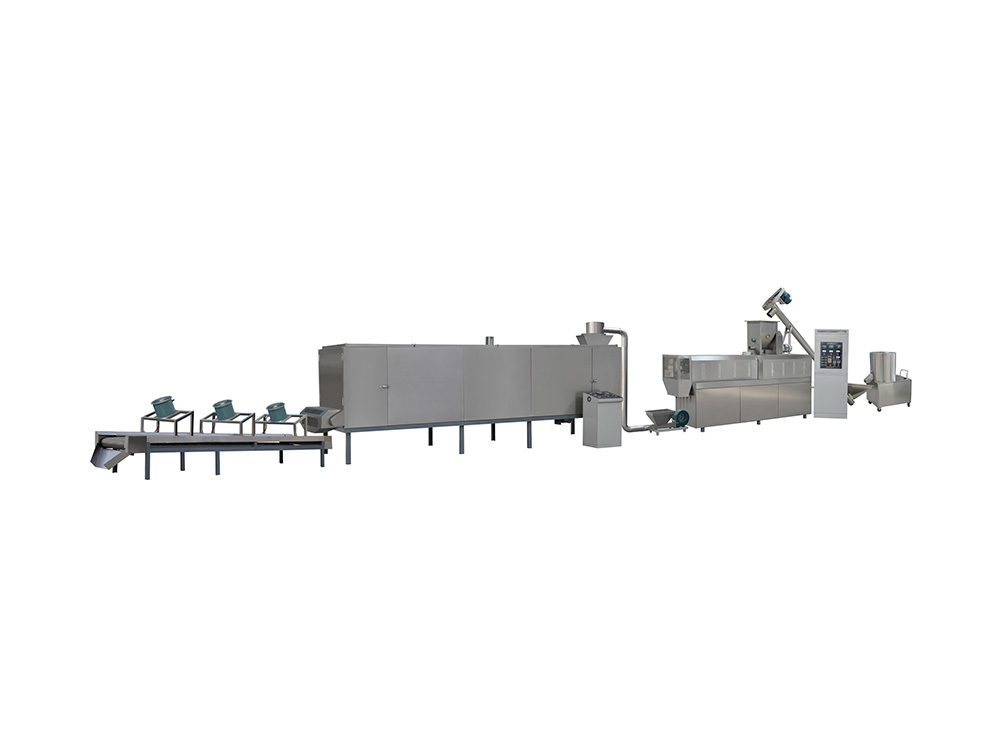

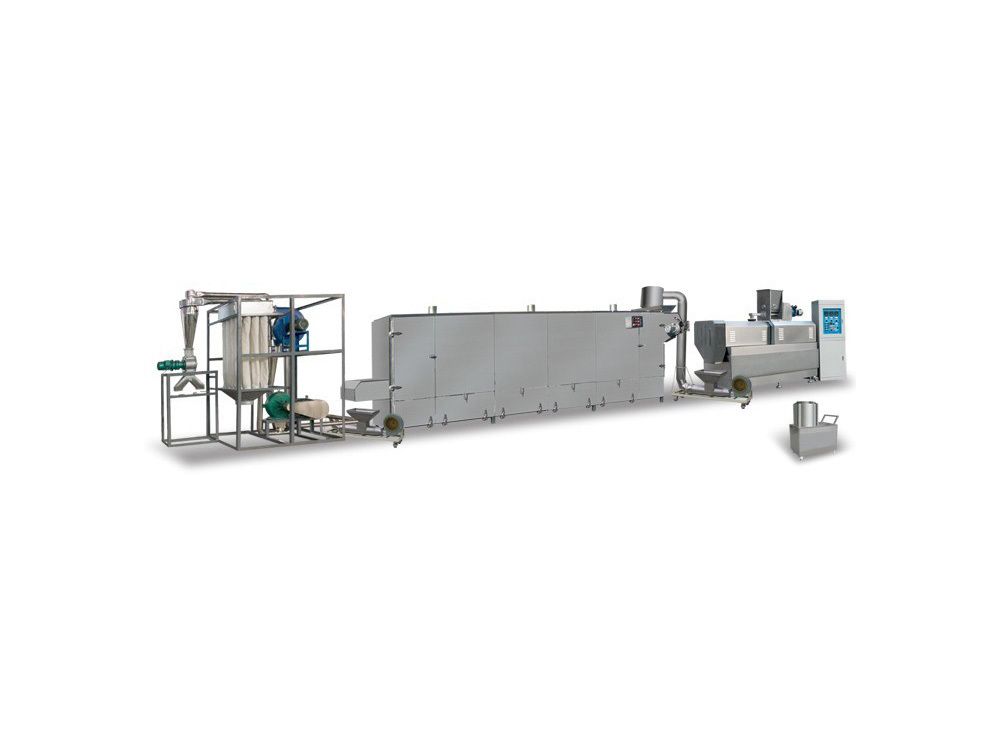

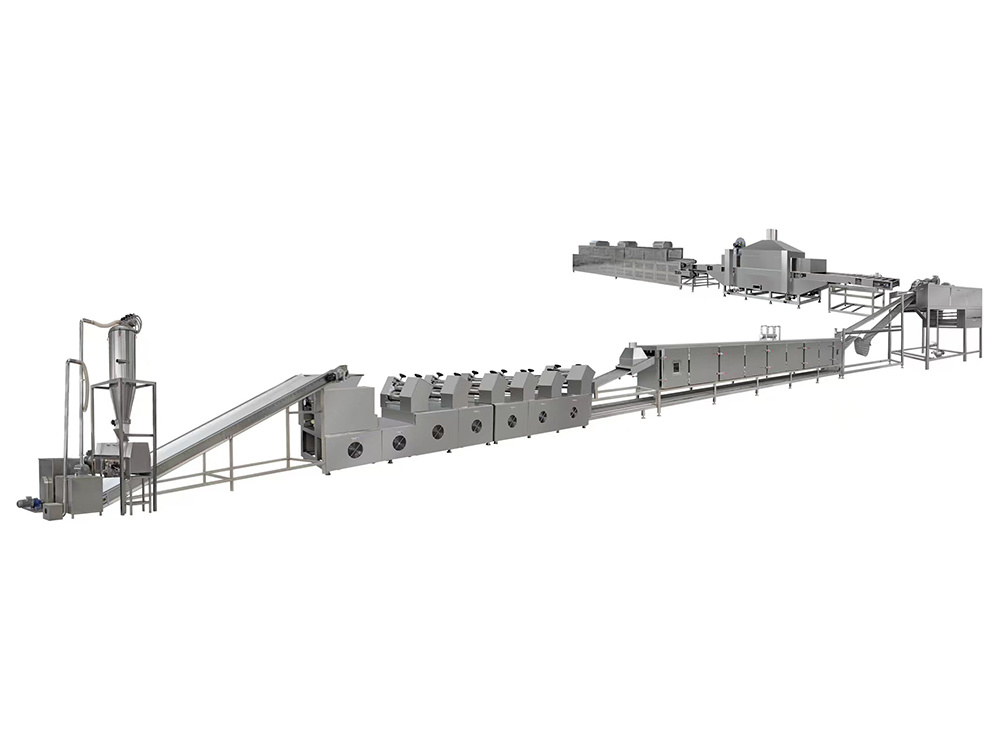

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

RELATED PRODUCTS

FAQ

March Trade Flash Sale: Shandong Raystone Heavy Machinery Unveils Deals!

Q:What's your after-sales service like?

Q: Can I get some samples?

Q: How long is your delivery time?

Q: Can we visit your factory?

Q: Are you a manufacturer?