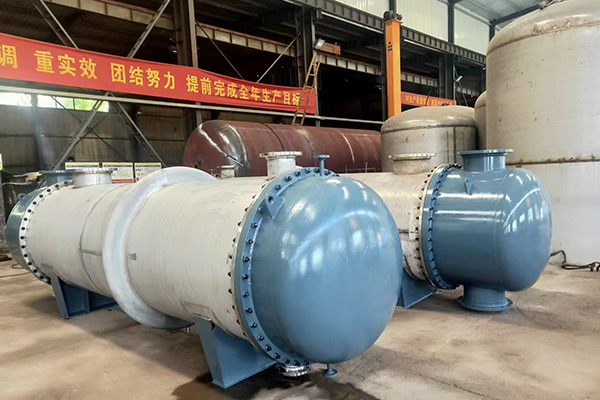

Pressure Vessels

Keywords : Raystone

Classification :

PRODUCT DETAILS

Keywords : Chemical pumps

Linerless composite pressure vessels are advanced pressure equipment with broad application prospects in many fields. They integrate many advantages of modern materials science and engineering technology.

1. Structure and Materials

Innovative Linerless Structure

Unlike traditional pressure vessels with liner, linerless composite pressure vessels adopt an innovative structural design. It directly uses composite materials to construct the pressure-bearing part of the container, eliminating the traditional component of the liner. This structure makes the container lighter as a whole, reduces unnecessary weight burden, and has great advantages in application scenarios with strict weight requirements, such as aerospace.

Linerless structure also avoids possible interface problems between the liner and the outer composite material, such as delamination and corrosion, and improves the overall reliability of the container.

High-performance composite materials

This pressure vessel is mainly made of high-performance fiber-reinforced composite materials. Commonly used fibers include carbon fiber, glass fiber, etc. Carbon fiber has extremely high strength and modulus, can withstand huge pressure, and its light weight helps to improve the performance-to-weight ratio of the container. Glass fiber has the advantages of low cost and good insulation, and can play a role in some applications that are more cost-sensitive or have special insulation requirements.

The matrix material usually uses high-performance resins, such as epoxy resins. The resin can firmly bond the fibers together to form an integral structure, and can transfer stress to ensure the stability of the container when under pressure.

2. Performance advantages

High pressure bearing capacity

Although there is no liner, linerless composite pressure vessels have excellent pressure bearing capacity. The laminated structure of the composite material can be optimized according to the actual pressure requirements, and can withstand high internal pressure by reasonably arranging the direction and number of layers of the fibers. In applications such as high-pressure gas storage and hydraulic systems, high-pressure media can be stored and transported safely and reliably.

Corrosion resistance

Due to the good chemical stability of the composite material itself, linerless composite pressure vessels have good tolerance to many corrosive media. Whether it is acidic, alkaline or some special chemicals, the container can resist its corrosion to a certain extent, which makes it possible to use it in corrosive environments such as chemical and marine environments.

Lightweight and portability

As mentioned earlier, its lightweight characteristics make it very suitable for mobile application scenarios. For example, in portable fuel cell systems, linerless composite pressure vessels can be used to store fuels such as hydrogen, which is convenient for transportation and use, and will not bring excessive burden to the entire system.

3. Application fields

Energy field

In new energy vehicles, it can be used to store high-pressure hydrogen or compressed natural gas, as a storage container for clean energy, to promote the zero-emission development of automobiles. In renewable energy storage systems, such as compressed air energy storage, it can also play an important role.

Aerospace field

Its lightweight and high pressure bearing capacity have an irreplaceable position in aerospace engineering. It can be used to store propellants, high-pressure gases, etc., which helps to reduce the weight of aircraft and improve payload and flight performance.

Industrial and special applications

In the chemical, petroleum, firefighting and other industries, it is used to store special gases or liquids to meet the needs of various industrial production and emergency rescue.

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

RELATED PRODUCTS

FAQ

March Trade Flash Sale: Shandong Raystone Heavy Machinery Unveils Deals!

Q:What's your after-sales service like?

Q: Can I get some samples?

Q: How long is your delivery time?

Q: Can we visit your factory?

Q: Are you a manufacturer?