Micro gear pump

Keywords : Raystone

Classification :

PRODUCT DETAILS

Keywords : Chemical pumps

Micro gear pump is a precision fluid delivery equipment. With its unique design and excellent performance, it plays an important role in many fields.

1. Structure and working principle

Exquisite structural design

Micro gear pump is mainly composed of pump body, a pair of meshing gears (driving gear and driven gear) and sealing components. The pump body is usually made of high-precision metal materials or engineering plastics to ensure the stability and durability of its structure.

The gear is small in size, but the manufacturing precision is extremely high, and the tooth shape is designed to be accurate to the micron level. This high-precision gear structure is the key to the Micro gear pump's ability to accurately deliver fluids.

Working principle

When the driving gear rotates under the drive of a power source such as a motor, the meshing driven gear also rotates. During the meshing process of the gears, the space between the teeth will form sealed chambers. As the gears rotate, these chambers continuously suck in fluid from the inlet side of the pump.

When the chamber rotates to the outlet side of the pump, the volume of the chamber decreases due to the meshing extrusion of the gears, so that the sucked fluid is discharged from the pump body at a certain pressure. This continuous suction and discharge process achieves stable fluid delivery.

2. Performance characteristics

Precise flow control

The flow of the Micro gear pump is proportional to the speed of the gear. By accurately controlling the speed of the gear, the fluid flow can be accurately adjusted. It performs well in some application scenarios with extremely high flow accuracy requirements, such as trace chemical reagent delivery in laboratories and high-precision quantitative injection of pharmaceuticals.

Its flow stability is also very good, and it is not affected by external pressure fluctuations, and can continuously and stably output the set flow of fluid.

Good self-priming ability

Since the rotation of the gear can form a certain vacuum at the inlet of the pump, the Micro gear pump has good self-priming ability. This allows it to easily suck fluid from a container with a lower liquid level without external auxiliary devices, which provides great convenience in many industrial and laboratory applications.

Adapt to a variety of fluids

The Micro gear pump can transport a variety of types of fluids, including low-viscosity liquids, such as various organic solvents, water, etc., and can also handle some medium and high viscosity fluids, such as grease, glue, etc. However, for high-viscosity fluids, it may be necessary to appropriately reduce the flow rate to ensure the normal operation of the pump.

3. Application fields

Medical industry

In medical devices, Micro gear pump is widely used in drug injection, hemodialysis equipment, etc. For example, in insulin pump, it can accurately deliver insulin to the body according to the patient's needs, providing a precise way of drug delivery for the treatment of diabetic patients.

Laboratory equipment

Used for micro-liquid transfer in chemical experiments, mobile phase delivery in chromatographic analysis instruments, etc. Its precise flow control and good self-priming ability can meet the strict requirements of the laboratory for fluid delivery.

Electronic industry

In the cooling system of electronic equipment, Micro gear pump can deliver coolant to ensure that electronic components work at a suitable temperature and improve the stability and service life of electronic equipment.

With its compact structure, precise flow control, good self-priming ability and wide adaptability, Micro gear pump has become an indispensable fluid delivery solution in modern industry, medical care and scientific research.

Product Parameters

|

Min inlet pressure: |

<0.2Mpa |

|

Working speed: |

5~200r/min |

|

Medium: |

Fluid |

|

Process temperature: |

<200°C |

|

Max Outlet pressure: |

<30Mpa |

|

Flow capacity:: |

0.15~3.6cc/r or 6-30cc/r |

|

Sealing: |

Combined seal |

|

Process temperature: |

<200°C |

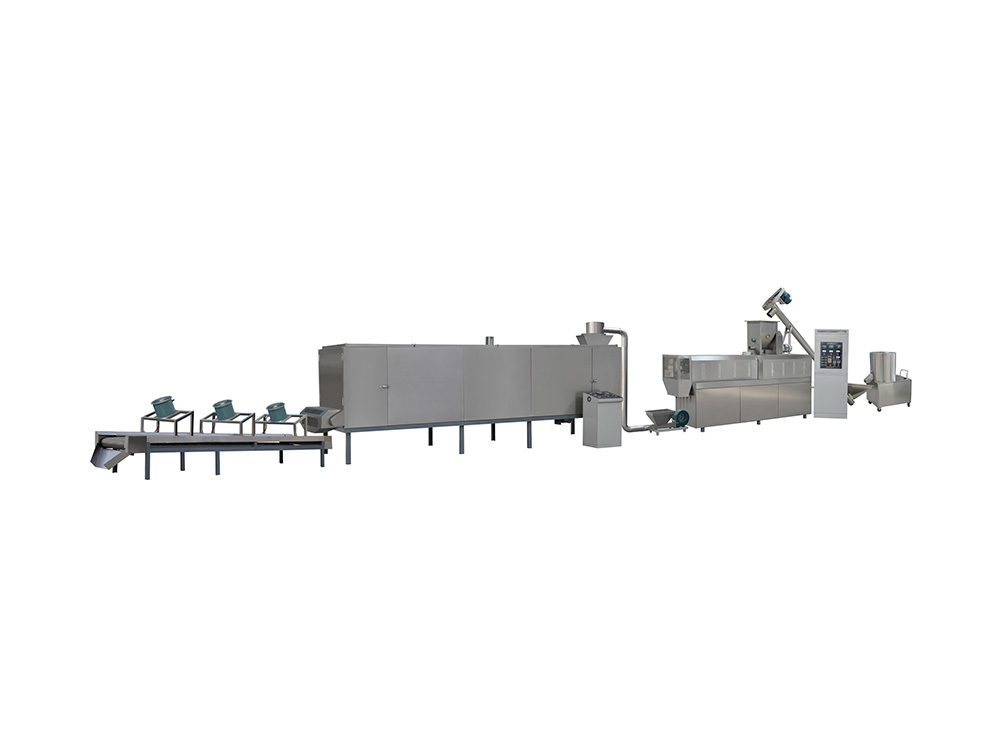

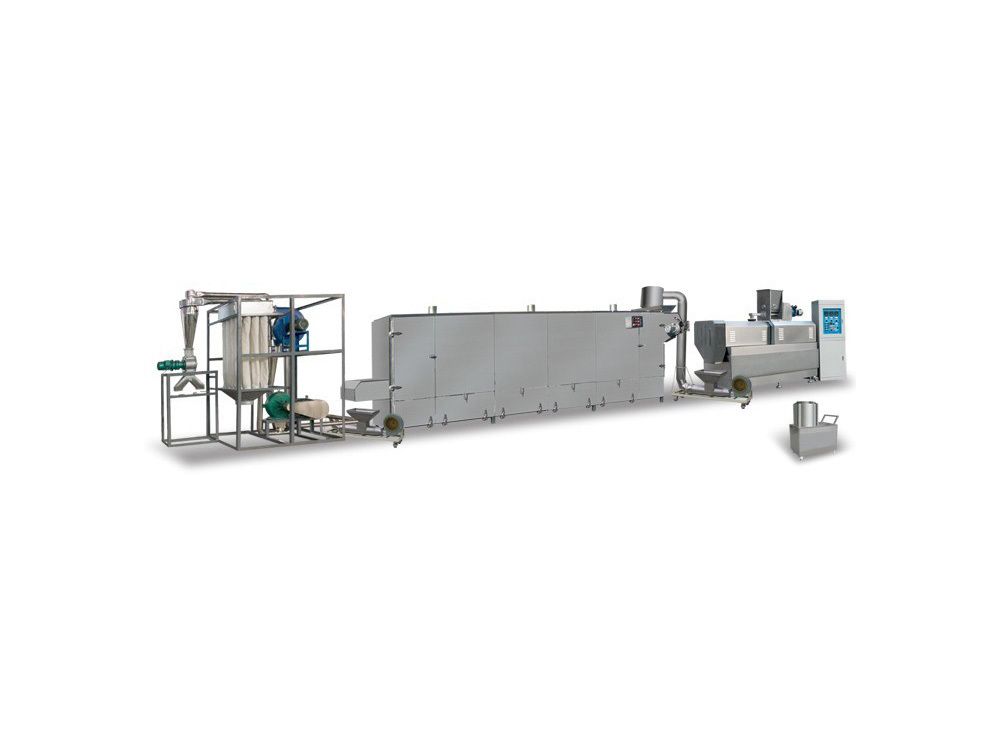

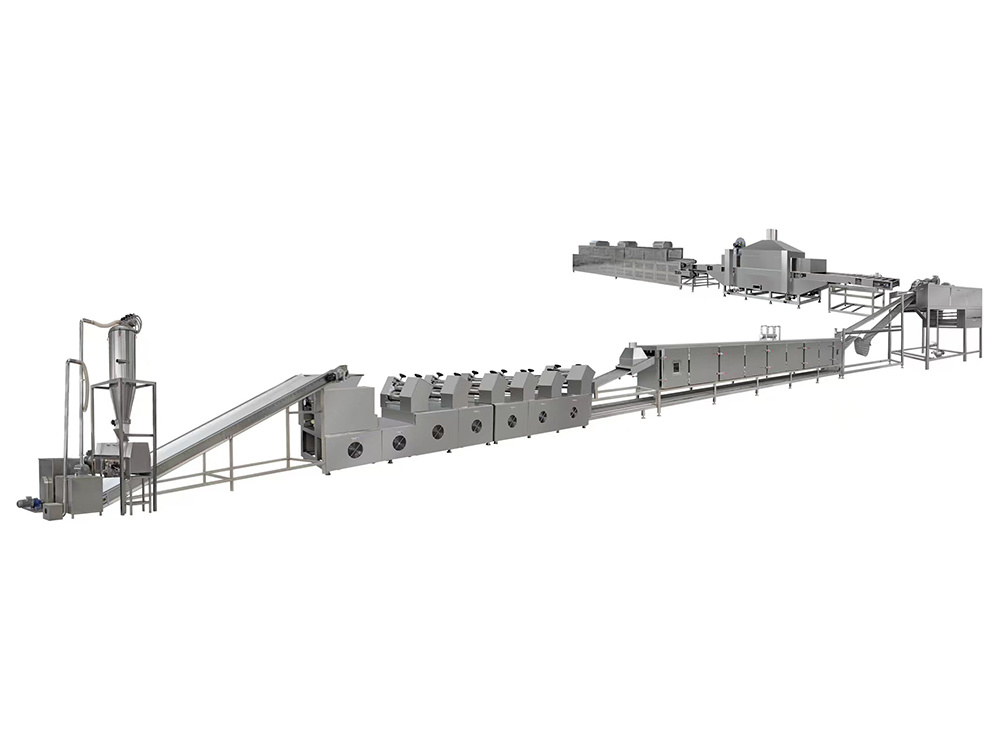

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

RELATED PRODUCTS

FAQ

March Trade Flash Sale: Shandong Raystone Heavy Machinery Unveils Deals!

Q:What's your after-sales service like?

Q: Can I get some samples?

Q: How long is your delivery time?

Q: Can we visit your factory?

Q: Are you a manufacturer?