Centrifugal Pumps

Keywords : Raystone

Classification :

PRODUCT DETAILS

Keywords : Chemical pumps

Screw centrifugal pumps are an innovative pump product that combines the advantages of screw pumps and centrifugal pumps.

1. Structure and Principle

Structural Composition

Screw centrifugal pumps are mainly composed of screw components and centrifugal components. The screw component has a special spiral shape that can initially push and pressurize the medium. The centrifugal component is similar to the impeller structure of a traditional centrifugal pump. When the screw pushes the medium to the centrifugal component, the impeller rotates at high speed, using centrifugal force to further increase the pressure of the medium and accelerate its discharge.

The pump body is usually made of high-strength metal materials to ensure that it can withstand the internal pressure, and the internal flow channel is carefully designed to ensure the smooth flow of the medium.

Working Principle

When working, the screw first rotates to suck the medium from the inlet and pushes it forward along the screw groove of the screw. In this process, the medium has gained a certain amount of pressure and kinetic energy. Subsequently, it enters the centrifugal component, and the rotation of the impeller causes the medium to flow toward the outlet of the pump body under the action of centrifugal force. In this process, the pressure is further greatly increased, thereby realizing the efficient delivery of the medium from the low-pressure area to the high-pressure area.

2. Product Advantages

High efficiency and energy saving

Due to the pre-pushing effect of the screw, the burden of the impeller directly handling large flow and low pressure media is reduced, and energy consumption is reduced. Compared with traditional centrifugal pumps, under the same flow and head requirements, it can save a certain amount of energy and reduce operating costs.

Good adaptability

Screw centrifugal pumps have strong adaptability to the medium and can transport media containing certain solid particles, fibers or viscosity. For example, in sewage treatment, sewage containing silt and fiber impurities can be transported without easy clogging. In the field of oil extraction, crude oil containing certain impurities such as paraffin can also be treated.

Stable flow and pressure

The coordinated work of the screw and centrifugal components makes the flow and pressure output of the pump relatively stable. In some industrial production processes with high requirements for flow and pressure stability, such as material transportation in chemical production and liquid medicine transportation in the pharmaceutical industry, the continuity and stability of the production process can be guaranteed.

3. Application Fields

Petrochemical

In the process of oil extraction, refining and chemical production, it is used to transport crude oil, various chemical raw materials and finished products. For example, it can transport crude oil from oil wells to refineries, and transport various corrosive or viscous chemicals in chemical workshops.

Wastewater treatment

As a key equipment for sewage lifting and transportation, it lifts sewage from the collection tank to the treatment unit, or transports the treated recycled water to the reuse site.

Food and Beverage

Screw centrifugal pumps are used to transport viscous materials such as juice, syrup, edible oil, etc. in various food and beverage categories to ensure stable transmission of materials on the production line.

The company has advanced production, testing equipment, has a stable supply and marketing partners at home and abroad, with the most professional team to do the best customer service.

Product Parameters

|

Product Name: |

Sanitary centrifugal pumnp |

|

3Material: |

SS316 or SS304 |

|

Standard: |

SMS. DIN. RIT.ISO/IDF |

|

Connection Way: |

Clamp, Male, Flange, Weld, Union |

|

Mechanisal Seal: |

C/SIC/EPDM,C/SIC/VITON |

|

Power: |

0.75Kw-7.5Kw |

|

Rate: |

50Hz or 60Hz |

|

Max. Flow: |

30 m3/H |

|

Max. Discharge Head: |

35 m |

|

Temperature Range: |

20°C~+120°C(68°F~248°F) |

|

Max. Rev.: |

2900 r/min |

|

Internal Surface Finishing: |

Ra-0.4um~0.8 umm |

|

Inner Surface Finishing: |

MMirror Polish |

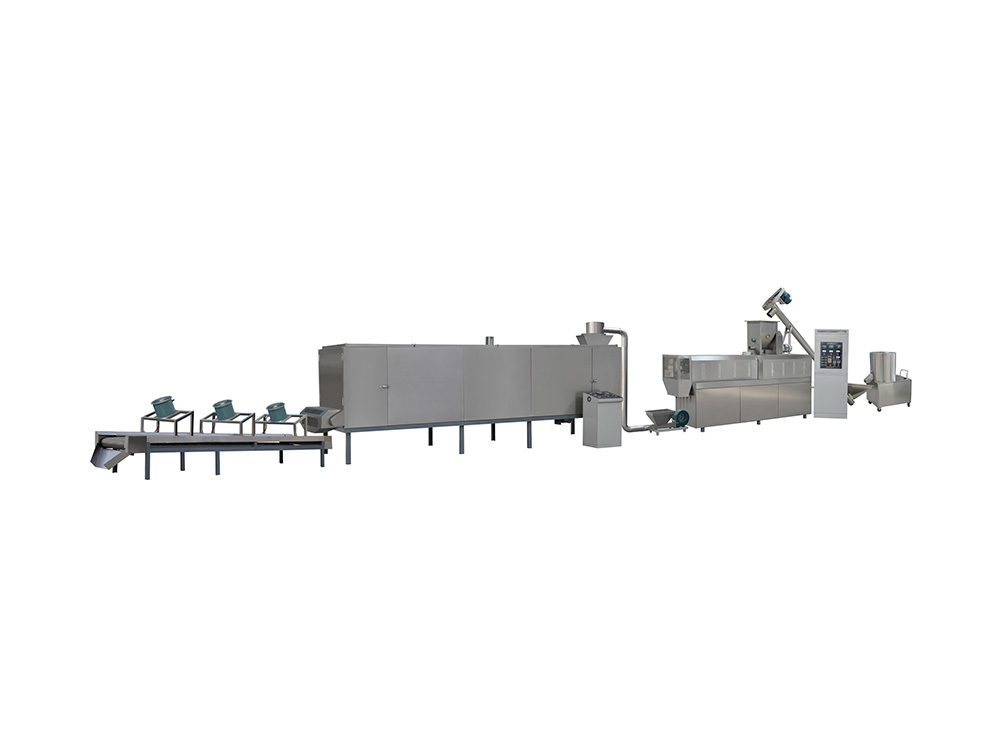

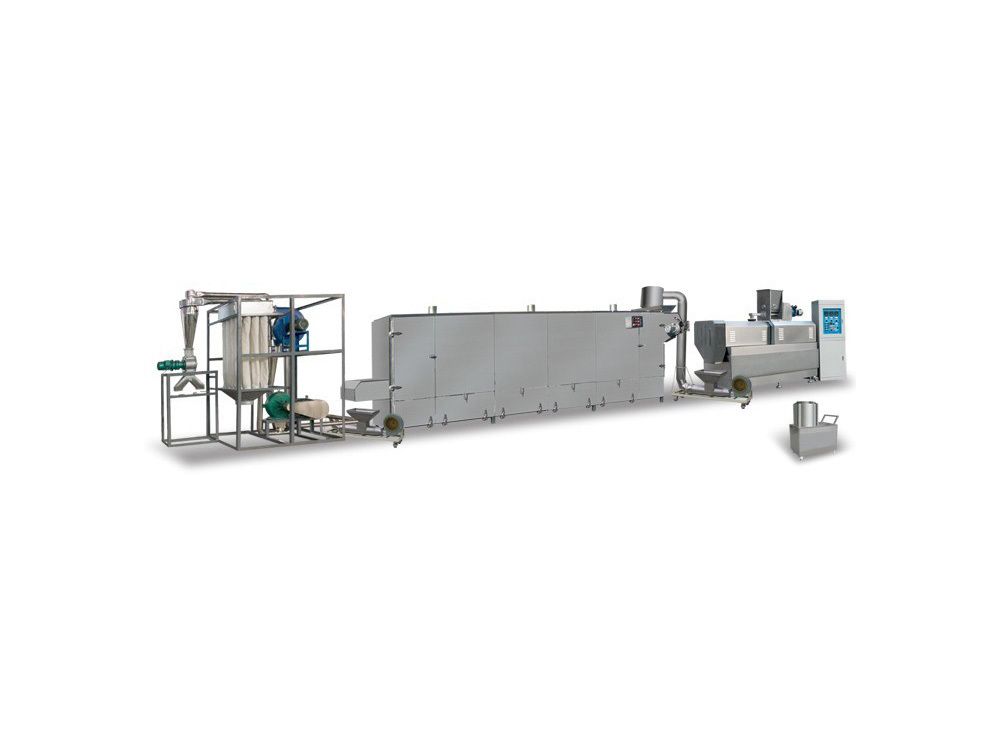

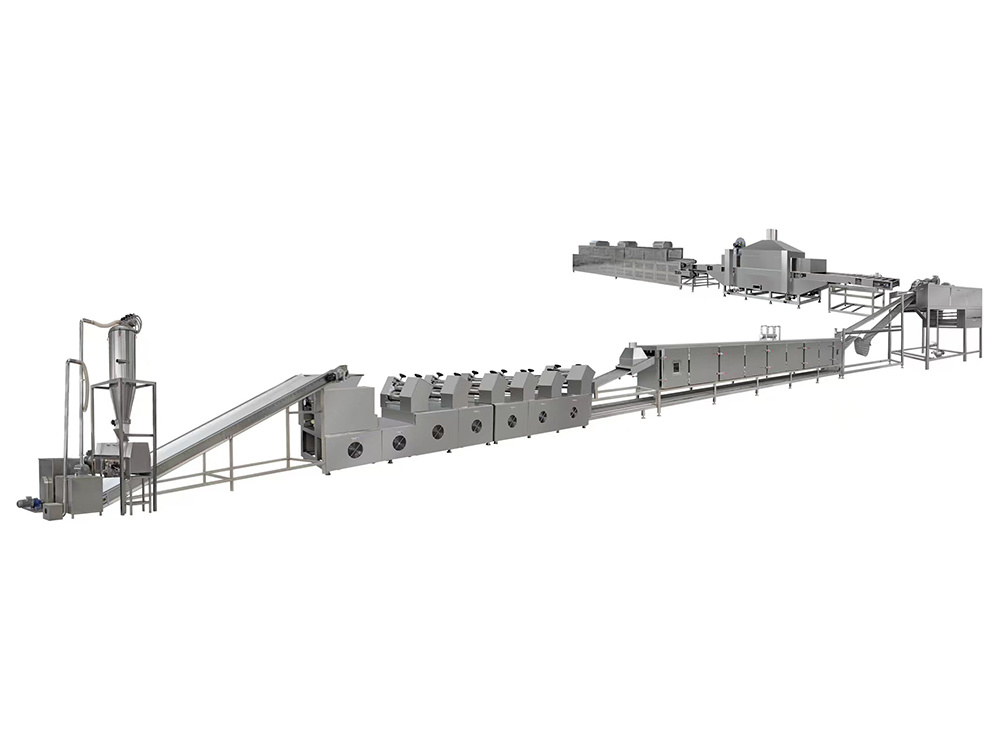

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

Factory workshop

RELATED PRODUCTS

FAQ

March Trade Flash Sale: Shandong Raystone Heavy Machinery Unveils Deals!

Q:What's your after-sales service like?

Q: Can I get some samples?

Q: How long is your delivery time?

Q: Can we visit your factory?

Q: Are you a manufacturer?