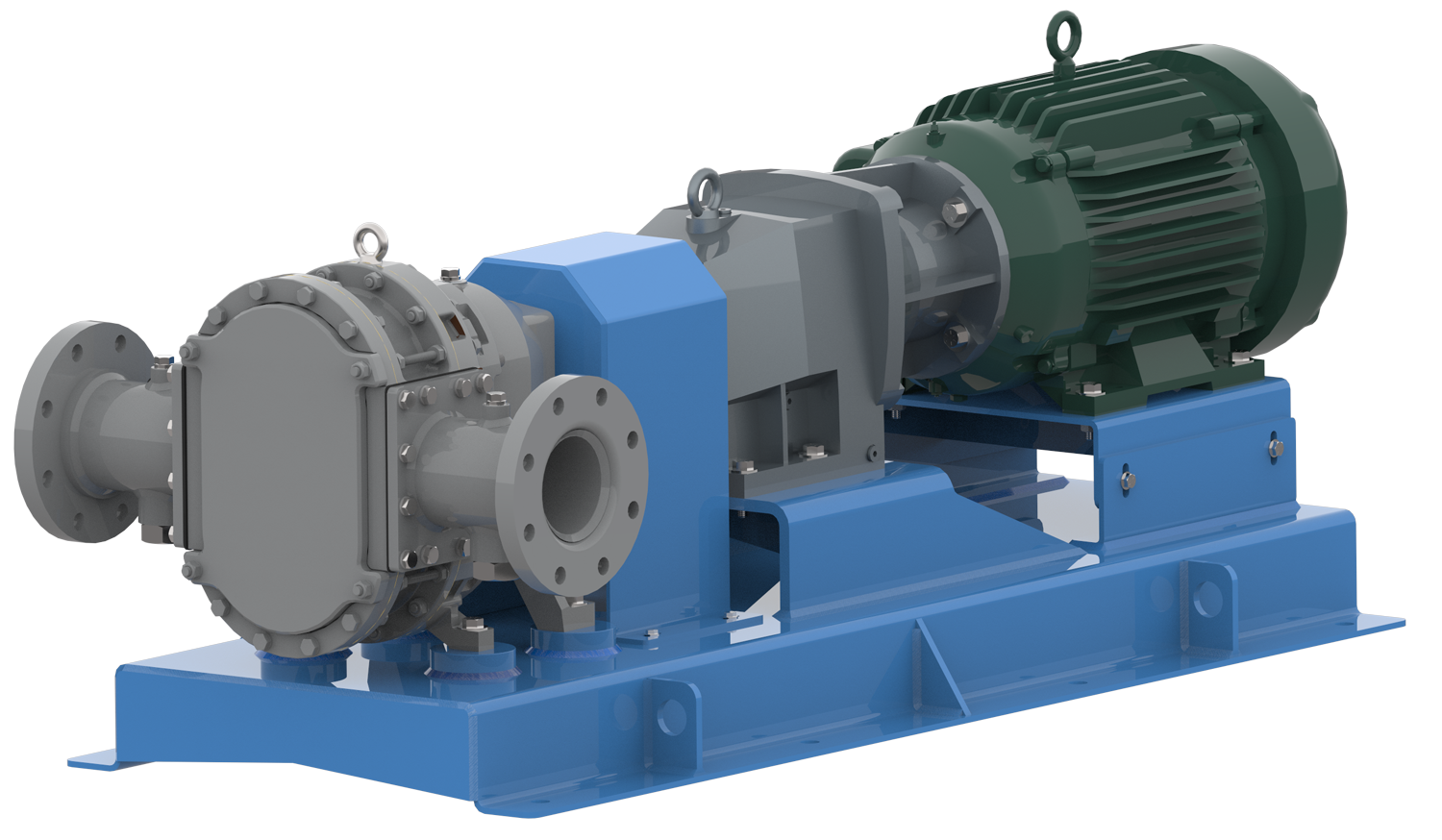

Rotary Lobe Pumps vs. Other Pump Types: Which Is Right for You?

Rotary Lobe Pumps vs. Other Pump Types: Which Is Right for You? Table of Contents Introduction to Pump Types Understanding Rotary Lobe Pumps How Rotary Lobe Pumps Work Advantages of Rotary Lobe Pumps Disadvantages of Rotary Lobe Pumps Comparison with Other Pump Types Applications of Rotary Lobe Pumps Making the Right Choice: Factors to Consider FAQs Conclusion Introduct

04

2025

/

10

Understanding Gasketed Plate Heat Exchangers: Efficiency and Applications in Industrial Settings

Gasketed plate heat exchangers (GPHEs) are pivotal in the realm of industrial equipment, specifically designed for efficient heat transfer between two fluids. These systems consist of a series of thin, corrugated plates held together by gaskets, creating a series of channel-like passages for the fluids. The design promotes effective thermal exchange while ensuring minimal pressure drop, making GPH

03

2025

/

10

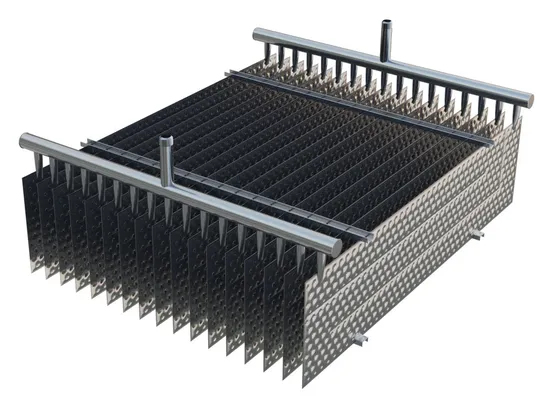

Finned Tube Heat Exchangers: A Comprehensive Guide to Their Functionality

Finned Tube Heat Exchangers: A Comprehensive Guide to Their Functionality Table of Contents 1. Introduction to Finned Tube Heat Exchangers 2. What Are Finned Tube Heat Exchangers? 3. How Do Finned Tube Heat Exchangers Work? 4. Benefits of Finned Tube Heat Exchangers 5. Applications of Finned Tube Heat Exchangers 6. Types of Finned Tube Heat Exchangers 7. Maintenance and Care of Finned Tube Heat E

02

2025

/

10

The Essential Guide to Liquid Metering Pumps: Understanding Their Role in Industrial Applications

Liquid metering pumps play a crucial role in various industrial applications, ensuring the precise delivery of liquids in processes ranging from chemical processing to water treatment. Their ability to accurately dose fluids makes them indispensable in many sectors, including pharmaceuticals, food and beverage, and manufacturing. Understanding the features and benefits of liquid metering pumps can

01

2025

/

10

Pillow Plate Heat Exchangers: The Key to Efficient Power Generation

Pillow Plate Heat Exchangers: The Key to Efficient Power Generation Table of Contents Introduction to Pillow Plate Heat Exchangers What Are Pillow Plate Heat Exchangers? Working Principle of Pillow Plate Heat Exchangers Advantages of Pillow Plate Heat Exchangers in Power Generation Applications of Pillow Plate Heat Exchangers Comparison with Other Heat Exchangers M

30

2025

/

09

best Carbon overwrapped pressure vessels

Our carbon overwrapped pressure vessels feature a metal or plastic liner wrapped with high-strength carbon fiber, which is then cured with a high-performance resin

29

2025

/

09